This post has been updated as: https://richardhess.com/notes/2007/03/21/soft-binder-syndrome-and-sticky-shed-syndrome/

For a current list of degrading analog tapes, click here.

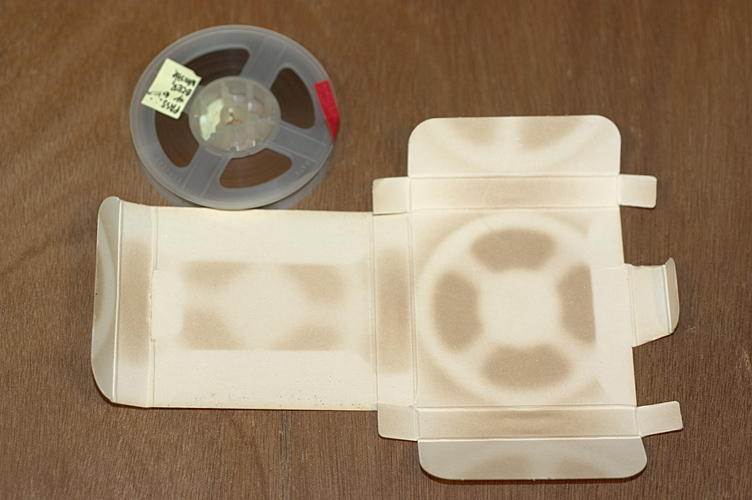

For several years, we have been discussing the differences between Sticky Shed Syndrome (SSS) and Loss of Lubricant (LoL).

Recent work in which I’m participating seems to indicate that what we thought was happening in both instances may not be really what is happening.

For now, the continued recommendation is to bake tapes for which baking works. These include:

Agfa (pre-1990): PEM 468, PEM 469

Ampex/Quantegy (1970s-1980s): 406, 407, 456, 457

Note: Recent reports indicate that these problems may exist in tapes made in the 1990s

and later, even under the Quantegy name.

Audiotape/Capitol (early 1980s): Q15

Note: This tape may or may not respond to baking. Some tests will be conducted soon.

Scotch/3M: 226, 227, 806, 807, 808, 809

If these are squealing and leaving deposits, they should be baked (at your own risk). The Ampex patent for baking tapes can be found here.

The classic test for determining if a tape is suffering from LoL has been to bake it and see that baking fails. The assumption has then been that it is loss of lubricant. This test, however, may exacerbate the condition and it is not recommended to bake suspected LoL tapes.

Tapes which appear to be suffering from LoL include:

Scotch/3M: 175 and Melody 169 (a seconds brand of Scotch)

Sony: PR-150

Pyral: (type numbers unknown for this French tape)

We have seen cassette tapes also suffering from LoL.

There are several ways to address playing LoL tapes, but, for the moment, we are not prepared to publish anything definitive beyond Marie O’Connell’s tried and true method shown here.