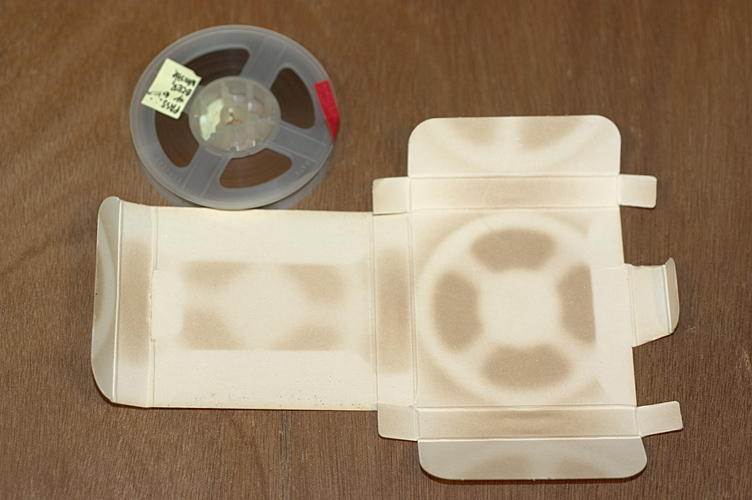

I spent days trying to get Shamrock 031 to play without much success. Since this is an Ampex factory budget brand (probably non-spec premium tape) I thought that it might be suffering from Sticky Shed Syndrome. I baked it for 12 hours and it still squealed. I then tried my usually successful cold playing technique and it still squealed. Cold playing has worked successfully with 3M 175 and Sony PR-150.

I was getting rather frustrated and since it was a four-track tape and one of the techniques that is supposed to reduce squeal is to play the tape faster, I dragged out my Racal Store 4DS instrumentation recorder which has a 75,000 Hz bandwidth at 15 in/s and played it at 15 in/s and digitized it at 88,200 samples per second. After slowing it down 4x and ending up with a 10 kHz bandwidth (which I subsequently truncated to 5 kHz since there was no useful information above that, but lots of noise–same as the non-squealing portion of the real-time transfers on a Studer A810).