For a current list of degrading analog tapes, click here.

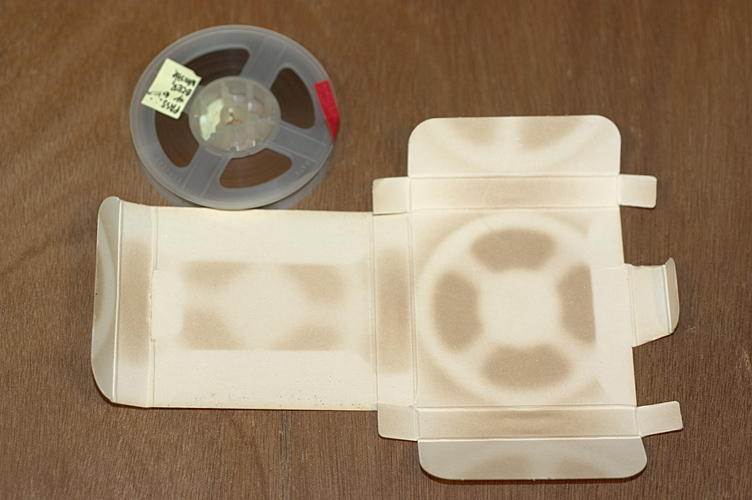

For several years, we have been discussing the differences between Sticky Shed Syndrome (SSS) and Loss of Lubricant (LoL). It appears from my latest research (presented at the 2006 Audio Engineering Society’s 121st Convention in San Francisco in October) that LoL does not really factor into the equation for most tapes and that an overarching failure mode is Soft Binder Syndrome, or SBS. Sticky Shed Syndrome appears to be a subset of SBS.